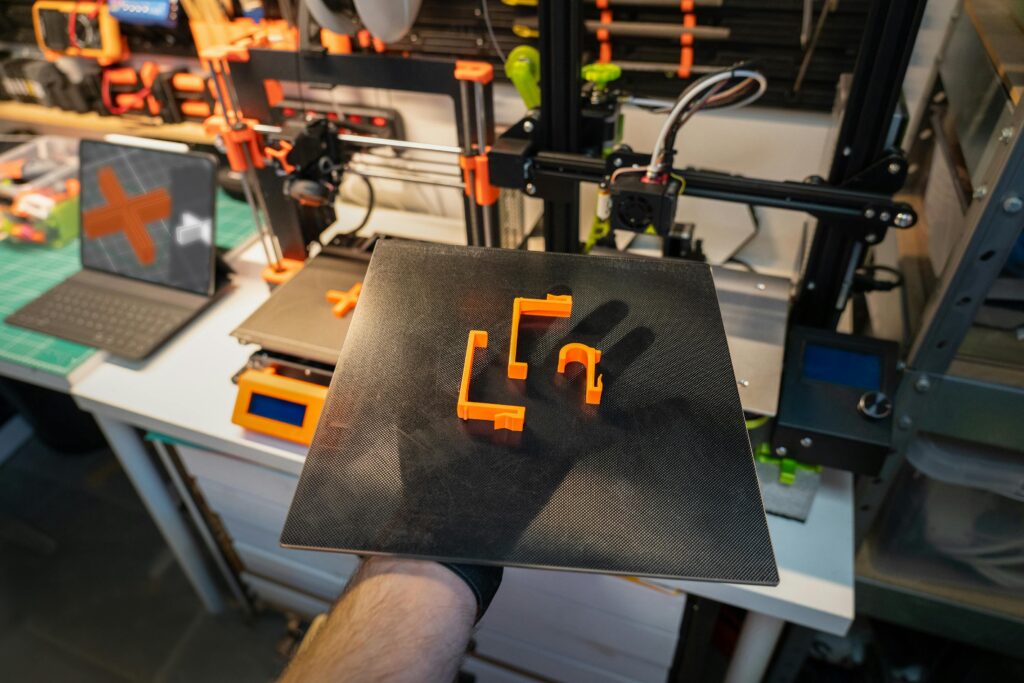

The future of 3D printing is rapidly evolving, with innovations and advancements reshaping how we approach manufacturing, design, and even daily life. As we move into 2024 and beyond, several key trends are poised to redefine the landscape of 3D printing. Whether you’re an industry professional, a hobbyist, or just curious about the future of 3D printing, these trends are worth keeping an eye on.

1. Mass Customization Becomes the Norm

In 2024, the future of 3D printing will see mass customization becoming more accessible thanks to advances in 3D printing technology. This trend allows consumers to personalize products according to their preferences without significant cost increases. From custom footwear and eyewear to tailored medical devices, the future of 3D printing enables the production of one-off items on a large scale, making mass customization a key trend to watch.

2. Sustainability Takes Center Stage

As global concerns about sustainability grow, the future of 3D printing is responding by developing more eco-friendly materials and processes. In 2024, expect to see a surge in the use of biodegradable filaments, recycled materials, and energy-efficient printing methods. Additionally, the future of 3D printing is reducing waste in traditional manufacturing by enabling more precise material usage. This focus on sustainability is not just a trend but a necessary evolution as industries strive to meet environmental standards and consumer expectations.

3. Advancements in Bioprinting

Bioprinting, the process of creating tissues and organs using 3D printing technology, is set to make significant strides in 2024. Researchers are pushing the boundaries of what’s possible, with the potential to create functional tissues for transplantation and drug testing. While fully 3D-printed organs may still be a few years away, the future of 3D printing will continue to revolutionize the medical field, offering new solutions for complex medical conditions.

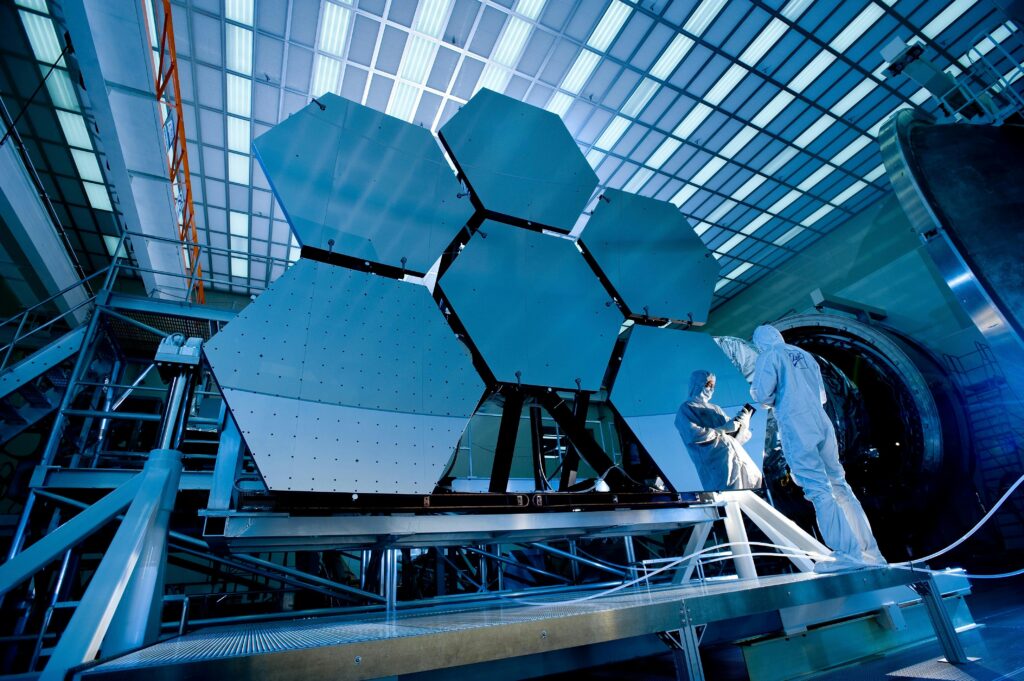

4. Increased Adoption of Metal 3D Printing

Metal 3D printing has been gaining traction in recent years, and 2024 will see even wider adoption across various industries, including aerospace, automotive, and healthcare. The ability to produce strong, lightweight metal components with intricate geometries that are impossible to achieve with traditional methods makes metal 3D printing an attractive option for manufacturers. As the technology becomes more affordable and accessible, the future of 3D printing will likely see it become a standard tool in high-precision manufacturing.

5. Integration with Industry 4.0

The convergence of 3D printing with Industry 4.0 technologies, such as IoT, AI, and robotics, is set to accelerate in 2024. This integration allows for smarter, more efficient production processes, with 3D printers capable of communicating with other machines, analyzing data in real-time, and making autonomous decisions. The future of 3D printing will lead to more streamlined and flexible manufacturing environments, reducing downtime and improving overall productivity.

6. New Materials Unlock New Possibilities

The development of new materials is one of the most exciting trends in the future of 3D printing for 2024. From advanced polymers and composites to conductive materials for electronics, the range of printable materials is expanding rapidly. These new materials are opening up possibilities in fields such as electronics, aerospace, and fashion, where traditional materials fall short. As material science advances, so too will the applications of the future of 3D printing.

7. On-Demand Production and Distributed Manufacturing

On-demand production and distributed manufacturing are poised to become more prevalent in 2024. The future of 3D printing allows companies to produce items as needed, reducing the need for large inventories and lowering storage costs. This trend is particularly relevant in the wake of supply chain disruptions, as it enables localized production closer to the point of consumption. Distributed manufacturing, where products are printed at multiple locations around the world, also reduces shipping times and carbon footprints, reflecting the future of 3D printing in a more sustainable and efficient global economy.

8. 3D Printing in Education and Training

As 3D printing technology becomes more mainstream, its integration into educational curricula is growing. In 2024, we can expect more schools and universities to adopt 3D printing as a tool for teaching design, engineering, and even biology. This hands-on approach to learning helps students develop critical skills for the future job market, illustrating the future of 3D printing in shaping the next generation. Additionally, online platforms offering 3D printing courses and tutorials are expanding, making it easier for anyone to learn and experiment with this technology, furthering the future of 3D printing in education.

9. Regulatory and Standardization Efforts

With the rapid advancement of 3D printing, there is a growing need for regulatory frameworks and industry standards. In 2024, expect to see more efforts to standardize 3D printing processes, materials, and safety protocols. These regulations will help ensure the quality and reliability of 3D-printed products, particularly in critical industries like healthcare and aerospace. As the technology matures, standardized practices will be essential for widespread adoption and trust, marking a significant aspect of the future of 3D printing.

10. The Rise of Hybrid Manufacturing

Hybrid manufacturing, which combines traditional manufacturing methods with 3D printing, is gaining traction as a way to capitalize on the strengths of both approaches. In 2024, more companies will adopt hybrid systems, allowing them to produce complex parts more efficiently and with greater precision. This approach is particularly useful for repair and maintenance, where 3D printing can be used to create replacement parts that are then integrated into existing assemblies, showcasing a pivotal element of the future of 3D printing.

Conclusion: The Future is Bright for 3D Printing

As we look ahead to 2024 and beyond, it’s clear that the future of 3D printing is poised to play a pivotal role in the future of manufacturing, healthcare, education, and more. The trends outlined above are just the beginning, as ongoing research and development continue to push the boundaries of what’s possible with this technology. Whether you’re an industry insider or just curious about the future of 3D printing, staying informed about these trends will keep you ahead of the curve in this rapidly evolving field.

By understanding and anticipating these developments, businesses and individuals can better position themselves to leverage the full potential of the future of 3D printing in the years to come. The future of 3D printing is not just exciting; it’s transformative.