The Future of 3D Printing

The 3D Printing is rapidly evolving, reshaping industries from manufacturing and healthcare to entertainment and retail. What started as a niche technology for prototyping has expanded into a key player in the global economy. As 3D printing and 3D design continue to advance, they are driving innovation, reducing production costs, and offering new opportunities for customization and sustainability.

In this article, we explore the future of the 3D business and how it’s set to revolutionize industries worldwide.

1. 3D Printing Revolutionizing Manufacturing

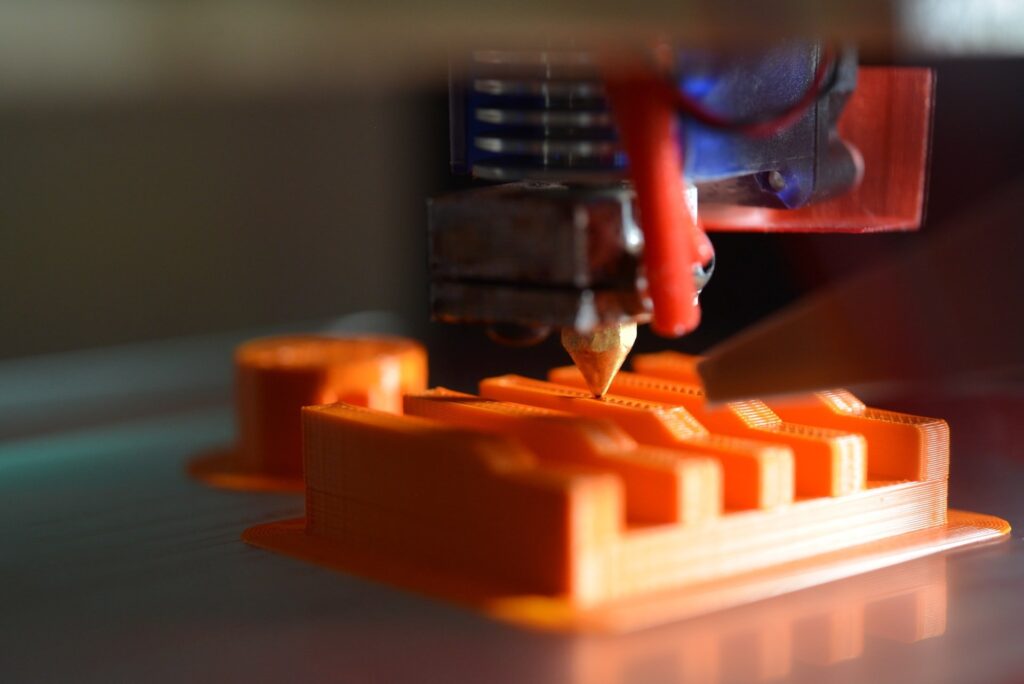

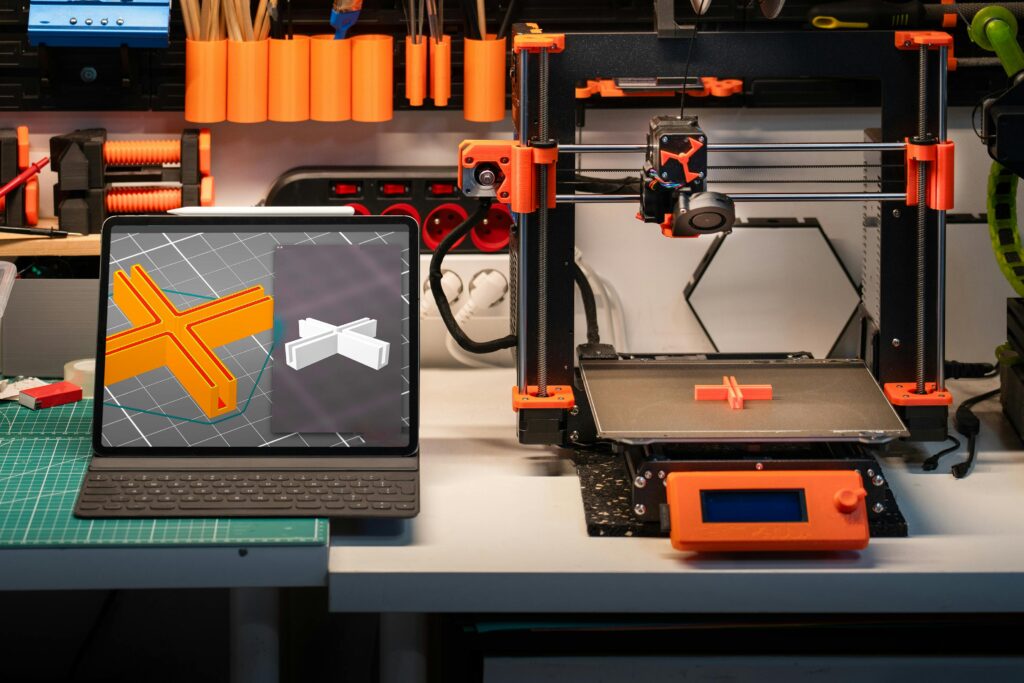

One of the most transformative aspects of the 3D business is additive manufacturing, or 3D printing. Initially used for prototyping, it has now moved into full-scale production, changing how goods are made. In the coming years, 3D printing will become even more mainstream in industries like automotive, aerospace, and consumer goods.

This shift will allow businesses to produce complex components faster and at lower costs. On-demand manufacturing will also become more common, reducing the need for large inventories and enabling companies to meet consumer demand in real-time. The ability to customize products at scale will give businesses a competitive edge in today’s market, where personalization is key.

2. Advances in 3D Printing Materials and Sustainability

As the 3D business grows, so does the variety of materials available for 3D printing. The future of the industry will see the rise of eco-friendly materials such as biodegradable plastics and metals. These materials will align with global sustainability efforts, making 3D printing a more environmentally responsible manufacturing option.

Additionally, recyclable 3D printing materials will become a focus, creating a more sustainable, circular economy. This shift will attract businesses looking to reduce their environmental impact and cater to an increasingly eco-conscious customer base.

3. Mass Customization: The Future of Product Personalization

Mass customization is set to be one of the biggest trends in the future of the 3D business. Consumers today crave personalized products, and 3D printing allows businesses to meet this demand efficiently. From custom shoes and jewelry to medical devices like personalized prosthetics, 3D printing makes it easier for companies to create unique products tailored to individual needs.

This trend is especially prominent in industries such as fashion, healthcare, and consumer electronics, where personalization is becoming a standard offering. Companies that embrace customized manufacturing will have the upper hand in a market that increasingly values personalization.

4. The Future of Healthcare: 3D Bioprinting and Medical Devices

One of the most promising applications of 3D printing lies in healthcare. 3D printing is already being used to create custom medical devices, from prosthetics to dental implants. But the real game-changer is bioprinting—the process of printing biological tissues and organs.

As bioprinting technology advances, the potential for printing functional human organs, such as hearts and kidneys, will become a reality. This will revolutionize organ transplantation, reducing wait times and saving lives. In the future, hospitals could be equipped with 3D bioprinters, capable of producing personalized medical implants or even organs on-demand.

5. 3D Design, Virtual Reality (VR), and Augmented Reality (AR) Integration

The combination of 3D design with virtual reality (VR) and augmented reality (AR) is set to change how industries operate. In fields like architecture, real estate, and interior design, clients can now experience virtual walkthroughs of their projects before construction even begins. This immersive experience allows for greater accuracy and customization in design.

In the gaming and entertainment industries, 3D modeling and VR/AR will continue to drive innovation, creating more realistic and interactive worlds. The integration of 3D technology with VR/AR will also help businesses offer enhanced customer experiences, from virtual shopping environments to interactive product demos.

6. 3D Printing in Logistics and On-Demand Production

Another exciting aspect of the future of 3D business is its potential to revolutionize logistics and supply chains. 3D printing makes it possible to produce goods locally, reducing the need for complex, global distribution networks. This shift toward on-demand production can lower transportation costs, reduce carbon emissions, and shorten delivery times for consumers.

We may soon see 3D printing hubs in urban areas, where consumers and businesses alike can print products locally. This decentralized approach to manufacturing will streamline production processes, offer greater flexibility, and help companies better respond to market demands.

7. Challenges Facing the 3D Business

While the future of 3D business is bright, there are challenges to overcome. One of the primary concerns is intellectual property (IP) protection. As 3D printing technology allows for easy replication of designs, businesses will need to develop new ways to safeguard their intellectual property.

Additionally, the widespread adoption of 3D printing will require a skilled workforce. 3D modeling, design, and production expertise will be in high demand, making it essential for companies to invest in training and education.

8. The Bright Future of 3D Business

The future of 3D business is full of exciting possibilities. As 3D printing becomes more advanced, businesses across industries will benefit from reduced costs, faster production times, and the ability to offer personalized products at scale. From bioprinting and customized manufacturing to sustainable materials and localized production, the potential of 3D technology is limitless.

As the 3D industry continues to evolve, businesses that embrace these advancements will be well-positioned for success. By staying ahead of the trends in 3D design, additive manufacturing, and customization, companies can transform their operations, meet changing consumer demands, and thrive in the future of 3D business.

Leading the Future

The 3D Printing is rapidly evolving, with significant advancements across manufacturing, materials, customization, healthcare, design, and logistics. Key trends include the shift toward additive manufacturing for large-scale production, enabling companies to produce complex, customized components more efficiently and cost-effectively. The industry is also moving toward sustainability, using eco-friendly materials that support a circular economy, which aligns with global environmental goals.

Mass customization and bioprinting offer transformative possibilities, from tailored consumer goods to 3D-printed medical devices and even potential organ transplants. The integration of 3D technology with VR/AR is enhancing customer experiences, allowing for immersive design and virtual walkthroughs.

Furthermore, 3D printing in logistics could lead to decentralized, on-demand production, reducing transportation needs and enhancing flexibility. However, challenges around intellectual property and the need for skilled professionals remain. Companies that adopt these innovations early will be positioned to lead in an industry primed for exponential growth and widespread adoption.